Back in April,I visited Gadget Show Live and saw a lot of innovations from car simulators to sophisticated DSLRs, but I’ve always been a sucker for those ones that stands out simply because of how it works.  3D printing have been around for years but as of late, it has picked up again maybe because we now have the need for fast things like fast food and the like.  3D printing is so fascinating that you almost feel like a kid in a candy store when shown the capabilities and the things you can print.  It has gone beyond just watching 3D movies, wishing you can print your own character whenever you want to a reality.

So I got in contact with 3D printing UK so I can get a closer one to one with the machine it’self and the man behind it; although it is a little different from the one I saw at the GSL, this one has it’s own advantages.

A little information about the 3D Print UK

3D Printuk is a state of the art 3d printing bureau producing 3D models from sketches, written descriptions and CAD files for architects, designers, exhibitors, medical purposes and more; they are able to produce models in hours not weeks and for a fraction of the cost of traditional model making techniques.  If you have an idea, simply present it to them and the rest is history; you don;t have to worry about been able to design the whole model because the level of creativity I saw is just what you need when designing new prototypes.

I wanted to find out myself about how it works, and although I could have read articles, watch videos however it is not the same experience as seeing it physically in action.

How Does 3D Printing Work?

3D printing, commonly known as ‘Additive Manufacture’ is a form of rapid prototyping where models are made layer by layer without the use of moulds.

There are many forms of additive manufacture which all work in slightly different ways, but essentially they all follow the same principals. Each different method has its advantages and drawbacks, whether it be better surface finish, stronger model for working prototypes or full colour models for display models.

What are the basics?

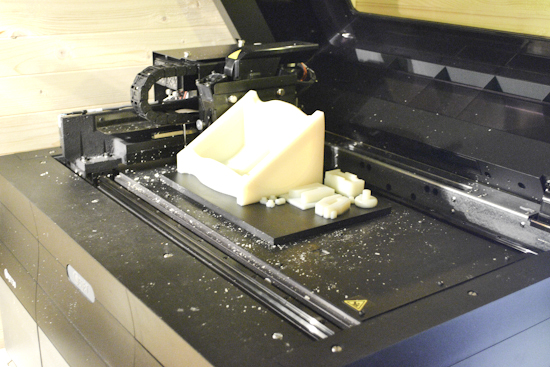

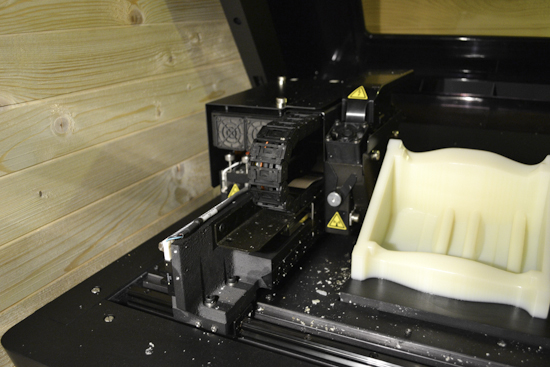

All 3D printers work from the bottom of the model up. The first layer is placed down on the build tray.

Much like an inkjet printer, the machines ‘draws’ out a cross section of the model across the X and Y axis. Once this has been completed, the build tray is lowered (i.e. the model moves down the Z axis) by a fraction of a millimetre and the process of drawing out another layer on the X and Y axis is repeated. This is performed over and over again until the entire model has been built.

Support Material

For any part of the model where there is an overhang or gap between moving parts, a support material is layed down (as it would be impossible to onto thin air!). Look at the example to the left of the 3dprintuk logo, notice how the support material is printed below any overhanging part, and how there is none above it, a good example is to look at the difference between the letter ‘n’ and the letter ‘u’ – they are the same shape, yet one uses far less support material than the other.

The support material is then removed once the print has finished to reveal the completed item. This can be done by washing, dissolving, breaking or hoovering away depending on the type of 3D printer is used.

Interesting Facts about 3D Printing

- You can print an array of various types of models from mechanisms like ball bearings, chains, even entire gearboxes can be printed in one go.

- You can print in colour

- No moulds are required, I must admit that was the first thought in my head when I pondered on how it would work.  Not using moulds would save time, cost and man power.

- With the caliber of operation involved, you might have a perception that it might take weeks or months to have a turn around but no you are wrong, it is very quick.

- One of the most exciting properties of 3D printing is that cost of manufacture is solely based on the volume of material used, so you don’t have to worry about how complex your model is, just fire away.

- You can print some pretty impressive impossible shapes. Â On my visit I saw some really cool objects printed, gallery and video will show you that later.

- The resolution on our 3D printers is as accurate as 0.028mm (0.001 inches), which is thinner than a human hair (average head hair is 0.1mm thick). The accuracy depends on which printer you are using – the Objet printer produces the most detailed of prints, where as the FDM machines are rougher, but produce stronger models.

- The materials used in 3D printing are not only limited to opaque plastics and ceramic powder based materials, there is now a huge range of mediums available to suit almost any type of product, and it is even possible to print in multiple materials in the same print; you might want to start printing your own gold bar replicas for decoration.

- The term Additive Manufacture means that materials are added layer by layer to make the final product, rather than traditional manufacture methods of Subtractive Manufacture, where a block of material has matter removed to produce the product. Other than a small amount of support material, there is very little wastage when a product is printed, and in some processes the support material is reusable.

Some cool 3D printed objects

[flagallery gid=27 name=”3DPrint”]Hands on Video with 3D Print UK

For more details or if you would like to order a 3D printing, then please visit 3D Print UK

![A Closer look at 3D Printing with 3D Printing UK [Video Inside]](https://www.gadgetsboy.co.uk/wp-content/uploads/2012/05/3dprint-550x336.png)